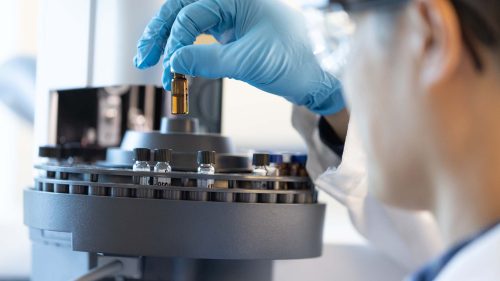

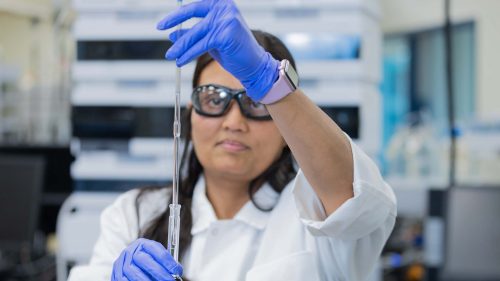

J-STAR Research provides analytical development and quality control (QC) expertise at all stages of Drug Substance (DS) and Drug Product (DP) development. Our team of expert scientists, equipped with tailored workflows and advanced instrumentation, delivers actionable insights that enhance product quality, reduce development timelines, and ensure regulatory compliance.

Our services include:

- Fast-paced and cost-efficient method development

- Comprehensive impurity profiling, including impurity identification and quantitation at all stages

- Excipient compatibility studies

- Method validation and verification

- Release testing for raw materials, registered starting materials, intermediates, APIs, and DPs

- Genotoxic impurity analysis

- ICH stability studies

- Forced degradation and degradation pathway understanding

- Analytical method troubleshooting